Introduction

The manufacturing industry of collectibles is undeniably a realm of creativity and diversity, where the choice of materials plays a paramount role. Today, we delve deep into two common yet vastly different materials: resin and plastic.

Origins of Resin and Plastic

Let’s begin by discussing their origins. Resin can be sourced from nature or synthesized artificially. Natural resins, such as pine and frankincense resin from trees, have been widely used in ancient times for incense and paint production. In contrast, synthetic resins are crafted through intricate chemical processes, like polyester and epoxy resins. Meanwhile, plastics have strong ties to petrochemical products.

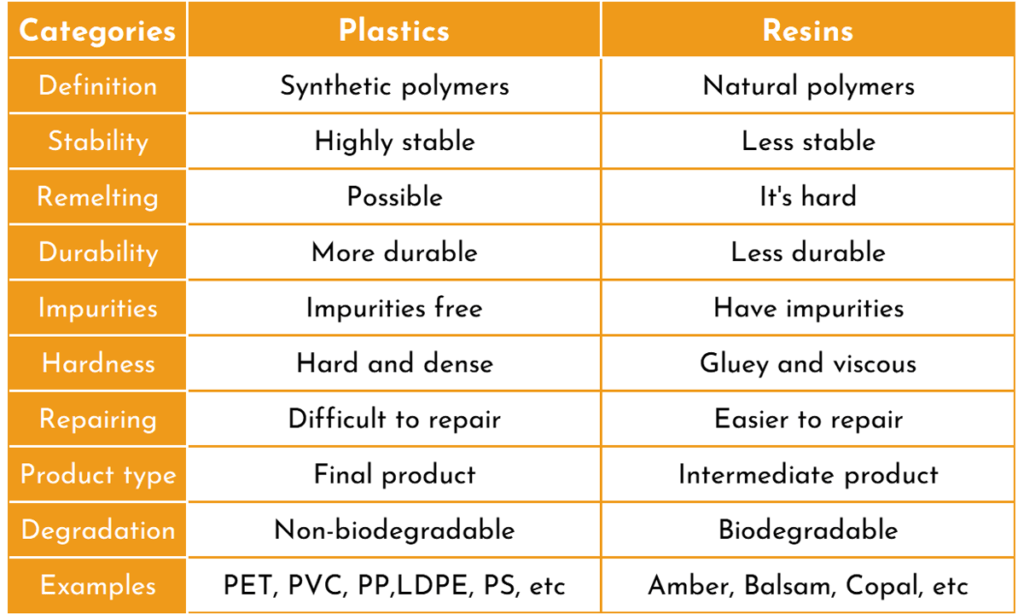

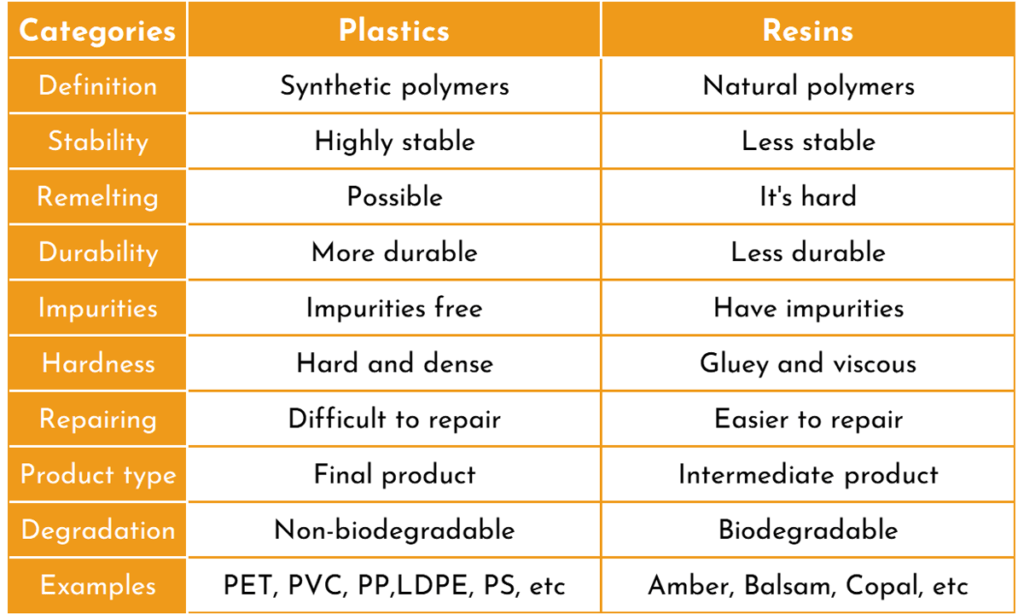

Comparison of Physical Properties

Next, let’s compare their physical properties. Resin is typically sturdier, more abrasion-resistant, and better at withstanding chemical corrosion. This makes resin the preferred choice for crafting items that require high durability. Moreover, resins generally boast superior transparency, making them excel in producing transparent or semi-transparent items, a vital aspect in the world of collectibles.

Plastics, on the other hand, come in a myriad of physical properties. They tend to be more flexible, making them easier to mold and process. The hardness, transparency, and chemical resistance of plastics depend on their specific composition and manufacturing processes. This diversity makes plastics the ideal choice for large-scale production of various items, whether household goods or a wide range of toys.

Practical Applications

So, what are their practical applications? Resin is often used to create high-quality collectibles, crafts, jewelry, models, and transparent components. Its reputation in the industry is significantly bolstered by its remarkable transparency, making it the go-to material for crafting transparent or semi-transparent collectibles and crafts.

Plastic enjoys widespread usage in the manufacturing of a plethora of items, from plastic containers and household goods to a wide variety of toys and industrial components. Its versatility and cost-effectiveness make it the perfect material for large-scale production and the creation of cost-sensitive items.

Consideration of Cost Factor

Lastly, let’s consider the cost factor. Due to their high quality and transparency, resin products typically come with a higher price tag, reflecting the attention to detail they exhibit. In contrast, plastics are generally more budget-friendly, making them suitable for large-scale production and the manufacture of cost-sensitive items.

Conclusion

In summary, resin and plastic each offer unique characteristics in the world of collectible manufacturing. The choice of material often depends on various factors, including product design, quality requirements, and cost considerations. In the world of collectible manufacturing, material choice directly shapes the quality and characteristics of the final product, opening up a world of possibilities for creators and collectors alike.