📌 Introduction📌

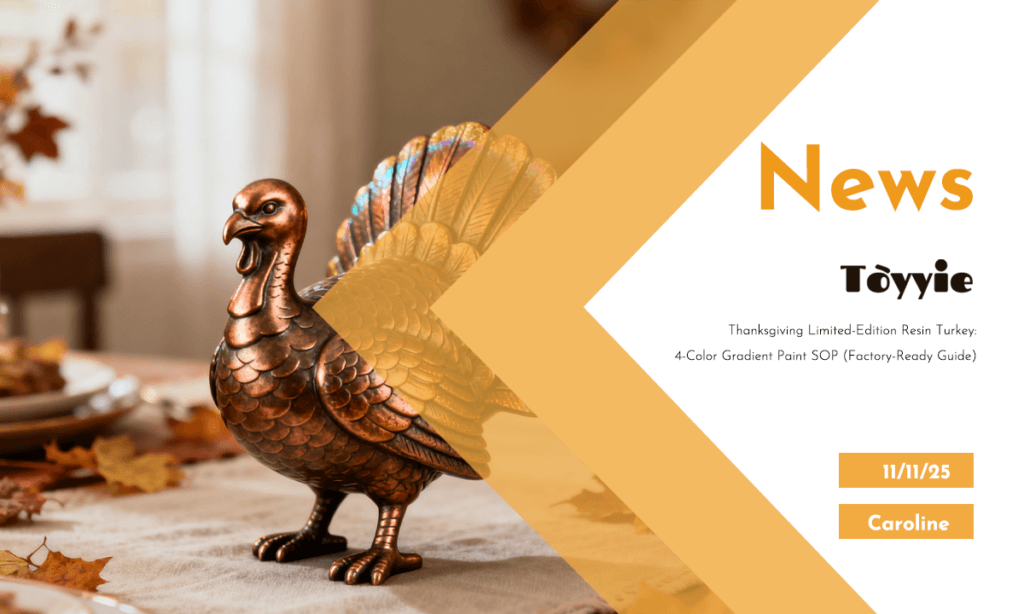

Every August, we receive requests from lifestyle brands, home decor labels, and gifting companies looking to launch a **premium Thanksgiving collectible**. Many want something beyond the typical cartoonish turkey — a piece that feels **artisanal, elegant, and seasonally meaningful**.

One of the most common asks?

> *“Can you create realistic feather depth with a multi-color gradient — at scale?”*

The answer is yes — but only with a **repeatable, factory-controlled process**.

At our Factory-based resin manufacturing facility, we’ve produced over **12,000 hand-finished resin turkeys** for U.S. and European brands. After three years of refining our technique — and scrapping early batches due to peeling paint and uneven blends — we’ve developed a **proven 4-color gradient spray SOP** that delivers consistent, high-end results on the production line.

Below, we share our full process — not as a marketing gimmick, but as a **transparent guide** for brands evaluating manufacturing partners.

🎯 The Vision: Natural Feather Depth in Four Tones

Our goal isn’t a glossy, plastic-looking bird.

We aim for **heritage turkey realism** — subtle shifts in color that mimic natural feather layers under light.

The palette is carefully selected:

– **Base**: Warm bronze (Pantone 7557 C) – sets the underlying tone

– **Mid-tone**: Deep copper (Pantone 7550 C) – adds shadow and volume

– **Highlight**: Golden amber (Pantone 7553 C) – brings light to feather tips

– **Edge Glow**: Custom interference pigment – creates a soft iridescent shift (gold to green)

This isn’t freehand artistry.

It’s a **structured, trainable process** designed for consistency across thousands of units.

🧼 Step 1: Surface Preparation – The Foundation of Adhesion

Resin is non-porous, making paint adhesion challenging. Without proper prep, even the best gradient will peel — especially at stress points like wing joints.

Our 3-step prep process ensures a clean, bond-ready surface:

1. **Light Sanding**: Feather areas lightly sanded with 600-grit paper to create micro-grip (body remains smooth).

2. **IPA Wipe**: Isopropyl alcohol removes oils and dust.

3. **Acrylic Primer**: A thin, fast-drying (90-second) water-based primer is applied for optimal paint adhesion.

> **Factory Insight**: Skipping the primer increases peel rate from **0.4% to over 30%**. We learned this the hard way on an early batch — now, it’s non-negotiable.

🎨 Step 2: The 4-Pass Spray Process (With Spray Path Diagram)

We use a **double-action airbrush** (0.3mm nozzle) at 30 PSI. Each color is applied in sequence, with drying time between stages.

**Pass 1: Base Layer – Warm Bronze**

– **Spray Path**: Top-down, even mist

– **Distance**: 15cm from surface

– **Drying Time**: 10 minutes (forced air)

– **Purpose**: Uniform foundation for all subsequent layers

**Pass 2: Mid-Tone – Deep Copper (Feather Zones Only)**

– **Spray Path**: Follow feather ridges from neck to tail

– **Technique**: “Pull and fade” — start with heavier deposit, lift at edges

– **Distance**: 10cm

– **Target Areas**: Back, wings, upper tail

– **Purpose**: Create depth and shadow

> **Pro Tip**: Artists are trained to follow the **anatomy of the feathers**, not apply color randomly. Consistency comes from muscle memory and guided paths.

**Pass 3: Highlight – Golden Amber (Tips Only)**

– **Spray Path**: Light mist on feather tips

– **Technique**: Quick tap-spray at 50% opacity

– **Distance**: 20cm

– **Purpose**: Simulate natural light catch

We perform a **backlight test** at this stage — if the tips glow softly, the highlight is correct.

**Pass 4: Edge Glow – Iridescent Sheen**

– **Spray Path**: Single, light pass along feather ridges

– **Coverage**: 10% (barely visible)

– **Distance**: 25cm

– **Purpose**: Add subtle shimmer — the “wow” factor

This final touch makes the piece feel alive under changing light.

⏳ Drying & Quality Control

After the final spray:

– **Flat drying**: 20 minutes (no stacking to avoid smudging)

– **Optional UV cure**: 5 minutes (for high-humidity markets)

– **QC Inspection**: Each piece checked for:

– Color bleed at joints

– Orange peel texture

– Gradient consistency

– Tackiness (touch test)

Our current defect rate: **1.8%** — down from 12% in our first year, thanks to process refinement.

📦 Case Study: “Heritage Harvest” Turkey for a U.S. Home Brand

**Client**: Premium home goods brand, U.S.-based

**Goal**: Thanksgiving centerpiece with “farm-to-table” elegance

**Specs**: 12cm resin turkey, matte finish, 4-color gradient

We followed the SOP above.

The client was initially skeptical about paint durability and realism.

After receiving a sample, they replied:

> *“It looks like it walked out of a Norman Rockwell painting.”*

**Result**:

– 3,000 units produced and shipped

– Zero returns

– Customer feedback included: *“Guests thought it was ceramic.”* and *“The feathers look unreal.”*

The brand later used our **spray path footage** in their product video, highlighting the craftsmanship behind the design.

⚠️ Common Pitfalls (And How to Avoid Them)

| Issue | Solution |

| **Paint peeling** | Always use a primer; avoid thick automotive paints |

| **Uneven gradients** | Train artists with guided spray paths; avoid freehand |

| **Orange peel texture** | Use airbrush-specific paints and proper thinner |

| **Smearing in humidity** | Control shop humidity; adjust thinner ratio seasonally |

✅ Why This Process Works for Brands

This SOP isn’t just about color — it’s about **delivering a premium unboxing experience** at scale. When customers see realistic feather depth and subtle light play, they perceive higher value — even at mid-tier price points.

**Key Benefits**:

– **Consistent quality** across large batches

– **Low defect rate** (under 2%)

– **No masking required** — faster production

– **Matte or soft-touch finish compatible**

– **Easy to brand** (optional base engraving, custom packaging)

Ready to Launch Your Holiday Resin Collectible?

Whether it’s a Thanksgiving turkey, holiday ornament, or seasonal centerpiece, we help brands bring **emotionally resonant, factory-perfected designs** to life.

Our team supports full turnkey production — from mold-making to painting, packaging, and logistics.

[Contact Us] to request a sample, review our spray templates, or discuss your 2025 holiday line.

Let’s create something that doesn’t just sit on a shelf — but starts a conversation.