Why Does Color Deviation Occur?

Differences Between Display and Print

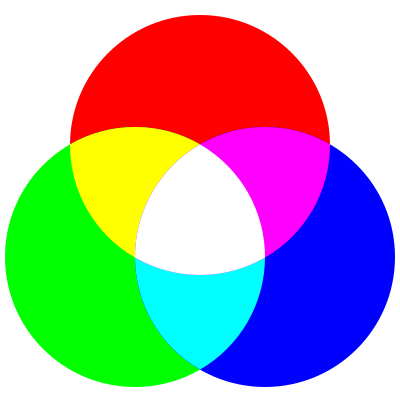

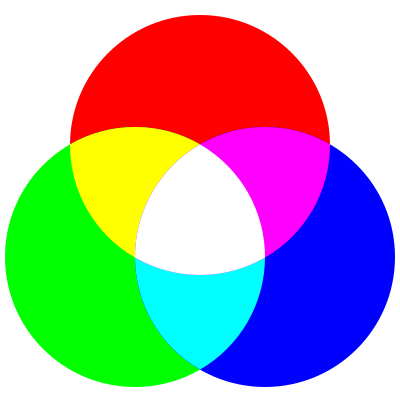

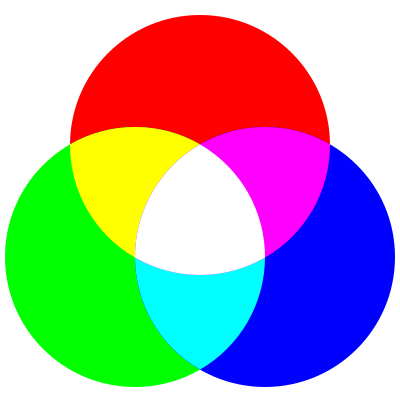

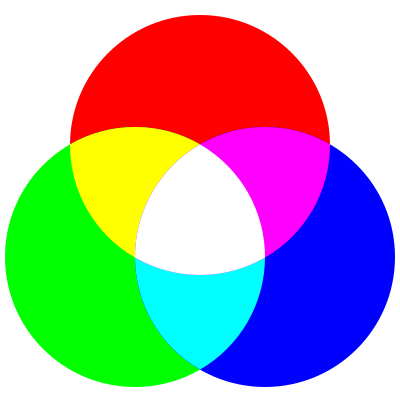

Your computer screen uses RGB (Red, Green, Blue) colors for display, while printing relies on the CMYK color model. These differences in color models inherently create disparities between what you see on your screen and the final printed result.

Your computer screen uses RGB (Red, Green, Blue) colors for display, while printing relies on the CMYK color model. These differences in color models inherently create disparities between what you see on your screen and the final printed result.

Environmental Variabilityt

Printing can be influenced by environmental factors such as temperature and humidity. Even within the same batch of print jobs, variations can occur due to changes in these environmental conditions.

Material Matters

The choice of printing material matters significantly. Different paper types or materials like coated paper, uncoated paper, or even paper with a colored base can all yield different results. Additionally, post-processing, such as applying a gloss or matte finish, can affect the final colors.

CMYK Color Limitations

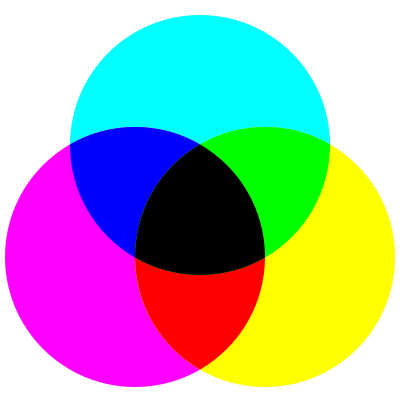

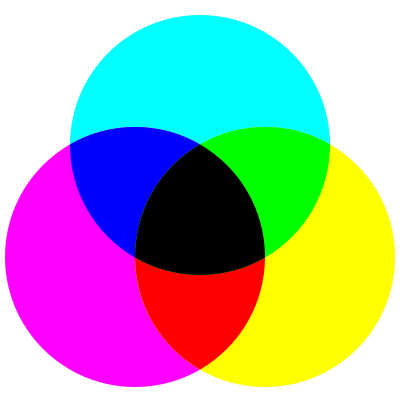

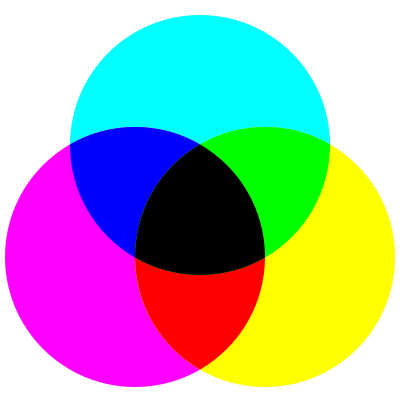

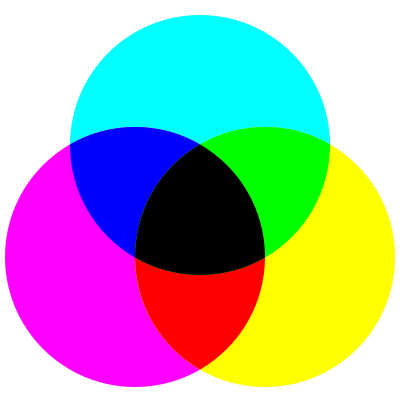

RGB colors use an additive model, where adding colors makes them brighter, while CMYK is subtractive, meaning more ink makes colors darker. Some bright or vivid RGB colors cannot be accurately reproduced in CMYK.

RGB colors use an additive model, where adding colors makes them brighter, while CMYK is subtractive, meaning more ink makes colors darker. Some bright or vivid RGB colors cannot be accurately reproduced in CMYK.

How to Avoid Color Deviation

Use Professional Design Software

When creating print materials, always use professional design software such as Adobe InDesign or Adobe Illustrator. These software tools allow you to work in the CMYK color mode and select precise colors.

When creating print materials, always use professional design software such as Adobe InDesign or Adobe Illustrator. These software tools allow you to work in the CMYK color mode and select precise colors.

Avoid Hard-to-Print Colors

Some colors, like deep blues, purples, oranges, and gradients with red tones, can be challenging to reproduce accurately. Avoid using such colors for critical design elements.

Selecting the right paper for your print job can significantly affect color output. Consider the characteristics of different paper types and choose one that aligns with your color expectations.

Paper Choice

Selecting the right paper for your print job can significantly affect color output. Consider the characteristics of different paper types and choose one that aligns with your color expectations.

Proof and Sign-off

If you have stringent color requirements, request a proof print and sign-off on it before proceeding with a full print run. This step ensures that you are satisfied with the color output.

Understand the Industry Tolerance

Most printing industry standards accept a color deviation within ±10% as normal. Understanding this tolerance range can help manage your color expectations. Understanding this tolerance range can help manage your color expectations.

Conclusion

Managing color deviations in printing is essential for achieving the desired results. While some color differences are unavoidable due to the nature of the printing process, understanding the factors that contribute to these deviations and taking proactive measures in your design and print processes can help you achieve the best possible results for your printed materials.