1. Selecting High-Quality Resin

The first and fundamental step in crafting exceptional resin toys is the careful selection of the right resin. Different resins possess distinct characteristics that significantly influence the texture and transparency of the final product. This crucial resin selection determines the colors and textures of the end product. For example, when aiming for a transparent or semi-transparent effect in your resin toy, we opt for PMMA (Polymethyl Methacrylate) resin, renowned for its exceptional transparency. Conversely, if your design calls for a robust texture, we choose a harder resin, such as epoxy, to ensure the toy delivers the desired tactile experience. Our resin selection is a meticulous process, ensuring it harmonizes perfectly with your design requirements.

2. Precision Color Blending

Color plays a pivotal role in resin toy design. We have a deep understanding of how to precisely blend pigments to ensure colors are vibrant, consistent, and align precisely with your design specifications. Each hue undergoes exact measurements and blending to guarantee an absence of any color deviations.

3. Accurate Pigment Incorporation

Accurate pigment incorporation is the linchpin for consistent colors. We employ precise tools and meticulously calibrated proportions for adding pigments, guaranteeing uniformity of color across every product. Pristine color preparation and application are paramount in achieving the anticipated color palette and texture of your resin toys. For instance, suppose you envision crafting a resin toy resembling the appearance of a ripe orange citrus fruit. In this case, our skilled color artisans select premium-quality orange pigments and ensure they are thoroughly blended with the resin to produce vivid and uniform colors. This process hinges on precision in measurements and extensive experience, as insufficient pigment may yield a pallid color that doesn’t align with the design, while an excess of pigment may lead to overly intense hues, straying from the intended design.

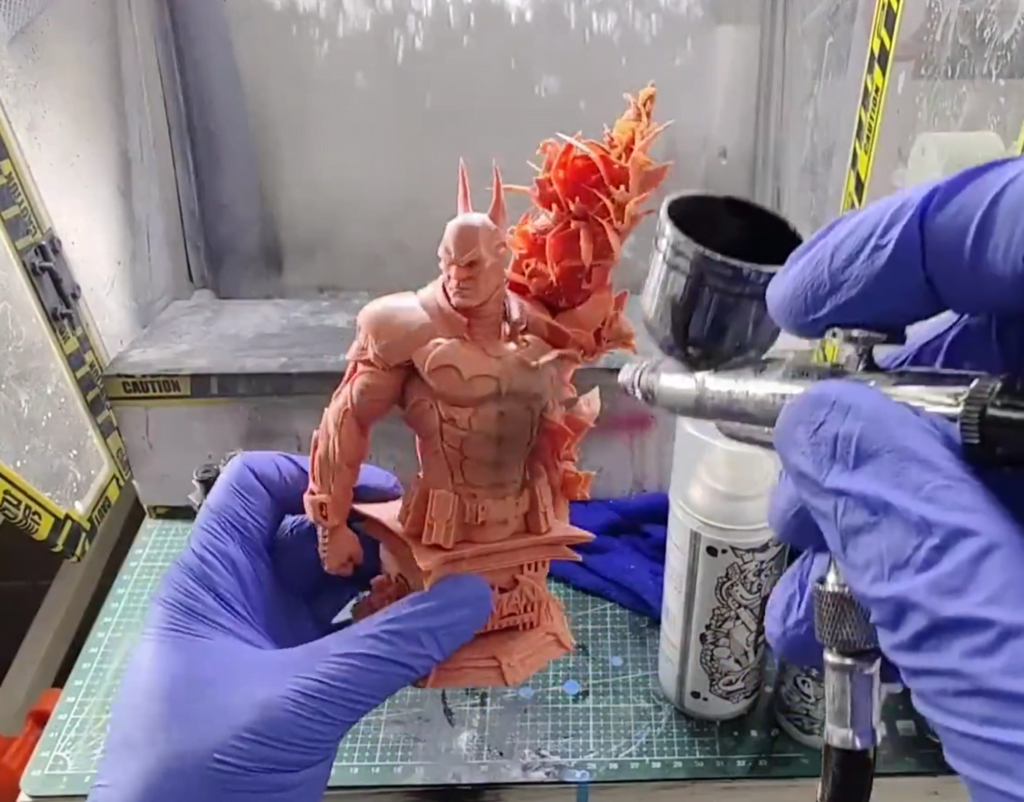

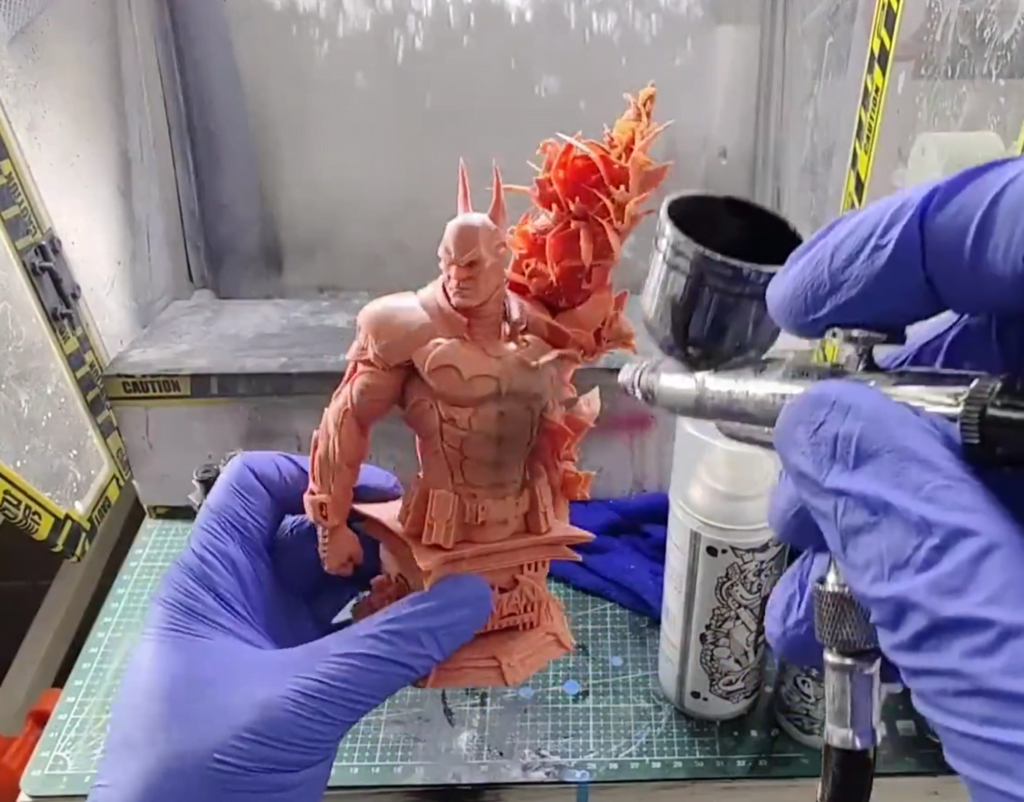

4. Seasoned Craftsmanship

Our workshop boasts a team of highly experienced craftsmen who have an intimate understanding of working with resin. They skillfully navigate the intricacies of the production process, ensuring each toy emerges with flawless perfection.

5. Stringent Quality Control

Multiple rounds of rigorous quality control checks are carried out to assure perfection in each resin toy. These assessments encompass a comprehensive review of color accuracy, texture, intricate details, and overall appearance. The presence of air bubbles is a potential factor that can compromise the texture of resin toys. To address this, we employ specialized equipment like vacuum degassing and employ air removal techniques, such as precise stirring, ensuring the resin remains as bubble-free as possible.

6. Iterative Testing

Prior to full-scale production, we undertake multiple phases of meticulous small-scale testing. These tests encompass assessments of color overlay, transparent effects, and intricate details. If any discrepancies emerge during these tests, we promptly make the necessary adjustments and corrections. For instance, when crafting intricate resin toys with multiple color layers, we conduct tests on small-scale models to evaluate different color overlay effects. These tests serve to identify and rectify potential issues, ensuring that the colors and textures of the final resin toys perfectly mirror your design.

7. Meticulous Attention to Detail

Throughout the entire manufacturing process, we maintain unwavering attention to every detail. This includes selecting the resin, blending colors, and executing quality control. Our commitment ensures no aspect goes unnoticed.

End

In the journey of creating resin toys, we meticulously navigate every step, guaranteeing the final product mirrors your design and showcases impeccable colors and textures. We understand your pursuit of excellence, and that’s precisely the standard we strive to uphold. When you choose to collaborate with us, you can have full confidence that your resin toys will be flawlessly presented.